My Chevy pickup

Chapter 0: How to buy a new truck

I bought this truck from Hall Chevrolet in Milwaukee, after they searched the Chevy database and found this was one of only three trucks at dealers in the upper Midwest that fit my criteria for a replacement truck (I was replacing the greatest vehicle I will ever have owned). My criteria were as follows:- Gas mileage equal or better to my last vehicle, a 1986 Toyota pickup

(27MPG), and

- Crew cab (for my wife and kids to be able to ride along).

- color

- options

- stereo

- type of seats

- Buy a used Toyota pickup truck, crew cab model, or

- Buy a rare Chevrolet Colorado with 4 cylinder engine and 5-speed manual transmission.

Chapter 1: The Honeymoon

The first 30,000 miles have been nothing but smooth sailing. The truck does not quite get 27MPG, but close to that. I installed some oversize wheel guards and a trailer hitch, and away I go. An oxygen sensor failed, and there was a factory recall for the brake light relay, both handled by the dealer at no cost to me.Since I moved from a 1986 model to a 2005 model, I expected to see some technology improvements that 19 years makes possible. There are a few big ones: the remote keyless entry is nice, the MP3 CD player is nice, and the ignition is automatic, so I don't have to think about how long to hold the key in "crank". The logic programmed into the headlights and door locks is unobtrusive, unlike some rental cars I have had that really annoyed me. So far... so good.

Chapter 2: Maximum Utility

Because the engine is "just" a 4 cylinder model, my truck does not have the same power that is very common for American drivers to expect.

Chapter 3: The Honeymoon Ends

Three years later, so the factory-installed battery died. No problem except that GM decided only to allow the dealer to supply direct replacements. Guess what? The default model battery is REALLY expensive. So my dealer offers a cheaper alternative: a battery that is the same function, made for the same truck, but manufactured in Korea instead of US. OK, I had to get out the plastic cutters to install it, but I did:

It seems a bit silly to have to modify the battery cover just to install a battery.

Chapter 4: Things Start to Go Wrong

At about 45K, the truck starts having fairly intense vibrations. I also start having intermittent speedometer failures where the speedometer just goes to zero, the cruise control then cuts out if it was on. This is pretty annoying. Finally, the blower motor stops working for low speed settings.

The dealer ends up replacing a driveshaft U-joint which had failed - that cured the vibrations. The speedometer sensor was fouled, perhaps as a result of the agitation of the transfer case from the vibration? The dealer cleaned it off and re-installed it. All this costs me more than $100.

Chapter 5: I Smell Lemons

Not so old, yet, but my truck is starting to show some age. What surprises me are the design flaws that this vehicle has... let's walk though a few.The Blower Motor

I'm not the only one to have seen this:

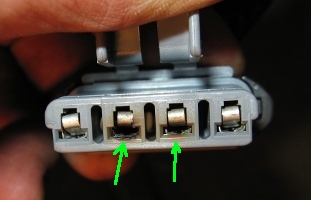

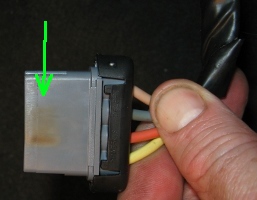

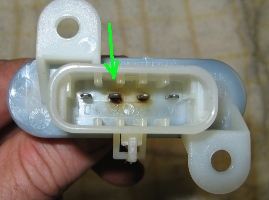

The wire harness to the blower motor dangles down into the passenger side foot area (left, above). The plug is pretty easy to jostle with your foot, and fits loosely in the socket (right, above). But it gets better! This is the harness for the resistor that allows the blower to run at different speeds. By kicking at the harness, I can usually get the blower to come on. This seemed lame, so I removed the resistor to examine the situation more closely, and here is what I found:

The resistor assembly (first picture) sticks into the air stream to cool it down, because it gets hot when the blower is used in slow speeds. But the plug (second and third picture, above) and the resistor socket (last picture, above) are burned because the connector is not rated for either the current or the heat of this application. This is why when you jiggle the connector (movie clip) the fan turns on and off. It's truly amazing how loose the connector is.

The Front Disc Brakes

The front disc brake pads got corroded and started sticking in the calipers. The result is that the brakes drag, overheat, and fail to operate properly. I had to have the rotors turned by the dealer and new pads installed for this, and it cost me more than $100. Many other accounts of this design flaw can be found on the 'net... once again I am not the only one to have this safety-threatening issue. The new pads seized in the calipers also, and I finally realized that I had to re-manufacture them in my shop, by grinding down the brake pad tabs to remove 0.5mm or so of material, then coat the tabs with anti-seize compound to make them work properly.

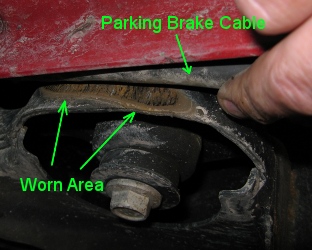

The Parking Brake

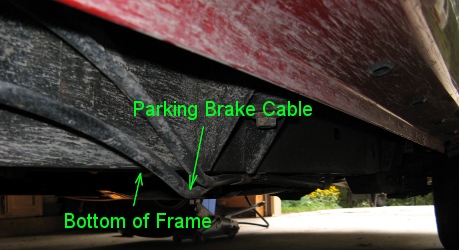

The parking brake cable is routed so that it dangles down below the frame (first picture). In many places it rubs against the frame, causing wear (second picture). Near the rear wheels there are boots intended to keep the outer part of the cable protected against rubbing, but these boots are made of cheap material and they rot away (last picture).

Finally, there are no return springs on the parking brake cable... so the brakes tend to remain engaged after release, only fully releasing when the cables work their way back as the vehicle vibrates. This is a serious safety flaw in the design of the rear brakes.

After the dragging rear brakes became unbearable, I did more troubleshooting and found the root cause:

In the first picture, the parking brake cable assembly removed from the vehicle (top) has a spot on the casing which is completely worn away by contact with a frame edge that it routes next to, with no tang or grommet provided to secure the cable from rubbing against the frame. The cable inside the casing is rusted and cannot move any longer. The new part from GM (second picture) has an additional pathetic plastic sheath which will certainly wear away in time as well, but it might take a little bit longer. Finally (last picture), my additional fix: a metal sheath added around the pathetic plastic one. The picture shows it installed so you can also see the frame edge that rubs and causes the wear in the first place.

Blinking Brake Lights

I noticed that the left-hand turn signal was sometimes blinking very fast compared to right hand turns. Then, after 5K miles, the left signal started turning on solid when the brake pedal is depressed. Back to the dealer... more money to fix, not sure exactly what issue this time.

Chapter 6: The End

At 65,500mi I am now ready to part with this vehicle. It's not a bad truck, and it does do what I wanted it to in terms of hauling and mileage, but it is sucking up my time and that's not what I want from a "new" vehicle. And... as an engineer I just can't be happy in something with this many fundamental design flaws. I think that GM owners might not know there's a better life, or they enjoy getting to know their dealer service department, but it just is not for me.

I sold the truck for $8200 on eBay - that means for the 5 years I drove it, I paid about $2500/year for it. In other words, more than the cost of the greatest vehicle I have ever owned each year.

Evidently, the GM life is just not a match for me. My last Chevy and I parted ways when it caught on fire in the junkyard driveway. So, on to the next vehicle... Toyota redux.