How to fix Bosch Dishwasher Panel

Solution

Remove the panel and fascia, repair the fascia plastic with steel-epoxy (e.g. "JB Weld") and reinforcing wire, and add a bolt to hold the fascia to the panel within the handle itself, not visible unless you look up into the handle.

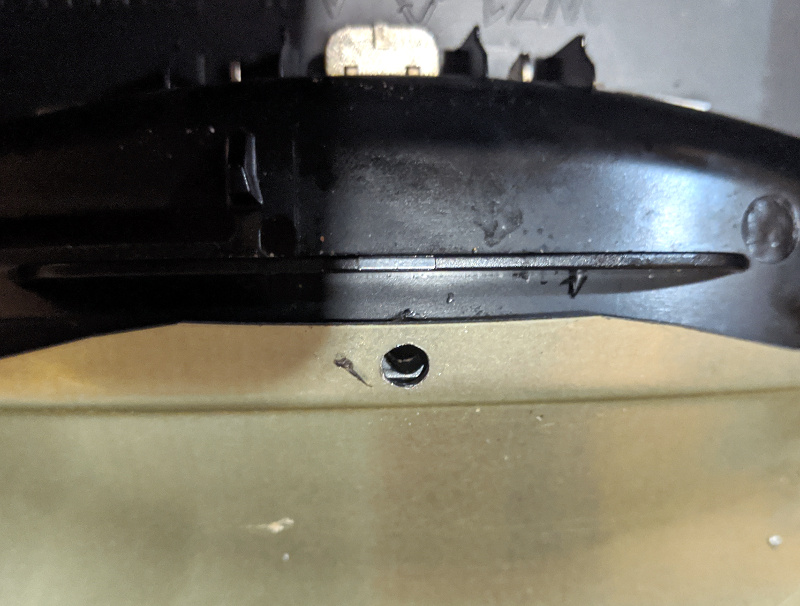

Here's where you add the bolt (circled in red):

This is a view from the back of the panel and fascia, holding them slightly separated.

Start by repairing the broken fascia. I used plastic model glue to glue the parts together, then reinforced each break with JB weld and a short piece of 22 gauge steel wire. Glue the parts together, then smear enough epoxy to cover the break, lay the wire on top and cover with more epoxy. Be careful not to glue the button hinges in the fascia, or build up the flat area on the bottom of the fascia that mates with the panel (dry fit them after gluing with model glue and before the epoxy, to see what I mean).

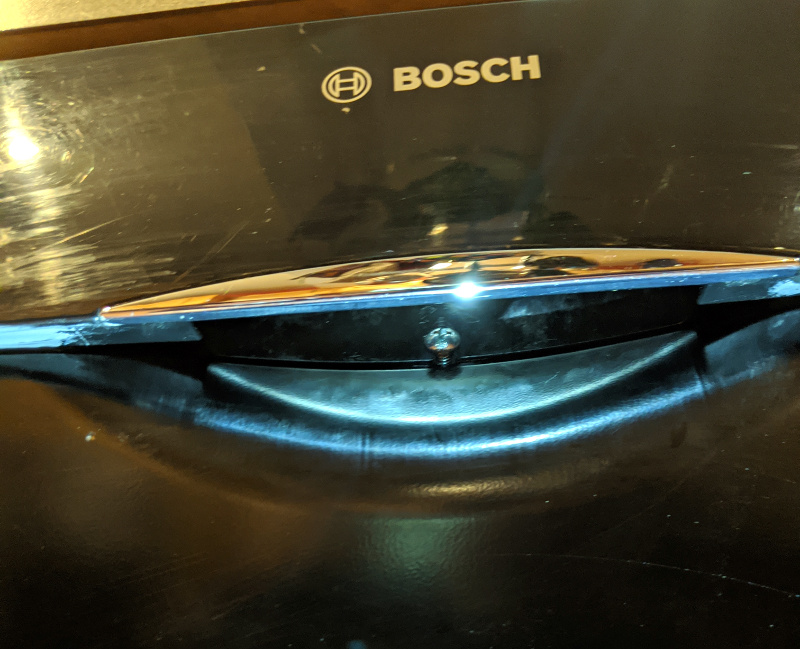

Next, drill a hole in the panel at the top of the indentation that forms the back of the handle:

Then fit the fascia to the panel and drill through the plastic handle

too:

I used a 3/16" drill bit which is the right size for a 10-32 bolt. You can obviously use whatever you have on hand.

Next, fit the two together, temporarily install the bolt and nut, and make sure it all lines up:

Once you are sure, either glue or weld the nut to the panel so that you can thread the bolt in from the front. I tack welded it. If you do that I suggest removing the fascia since the heat from the weld will melt the plastic.

Install all the pieces, thread your bolt through and snug it, and you are done! This makes the handle very strong and prevents the fascia from breaking again. Here's a view from the floor, showing the bolt:

(2 years later) The fix is still working, no issues.